Nikon D4 + Voigtländer 125mm f/2.5 — 1/800 sec, f/5.6, ISO 6400 — image data

Giving It Another Try

K-EDGE has restored my trust in its mount

Two weeks ago in “Pleasant Social Ride to Onyu Pass” I reported about how the K-EDGE bicycle mount for my cycling computer and front video camera had failed on a bumpy downhill. I had been using a K-EDGE Garmin Mount XL to hold a Garmin Edge 820 and a Cycliq Fly12.

The summary of this followup is that I am now using another copy of the same mount, and that I think it can be trusted if you don't touch the two screws joining the halves of the mount together. Details follow.

In the post two weeks ago, I included this photo showing the bike-side half of the mount with part of a sheared-off bolt sticking out:

Nikon D4 + Venus 60mm Super Macro f/2.8 — 1/320 sec, f/5.6, ISO 6400 — image data

Fate of the Earlier Mount

one bolt gone, the other ripped in half

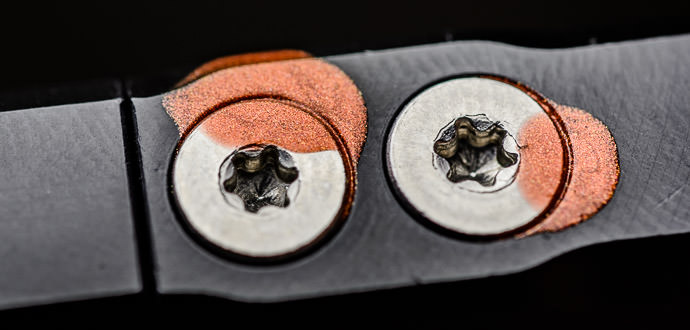

Modern mounts from K-EDGE see to come in halves joined by two screws:

Nikon D4 + Voigtländer 125mm f/2.5 — 1/320 sec, f/5.6, ISO 6400 — image data

Junction Between the Halves

Nikon D4 + Venus 60mm Super Macro f/2.8 — 1/640 sec, f/5.6, ISO 3600 — image data

Accessory Side of the Mount

with holes for two screws

I suppose this two-part design makes it easier to offer a wide variety of bike-mount solutions, since they don't have to design and manufacture every permutation of “attaches this way” and “supports these accessories”. Having mutually-interchangeable halves lets them mix and match on the fly.

To recap about the failure I experienced two weeks ago, while riding down a very fast, bumpy descent, the whole thing appeared to snap in half at a particularly nasty bump. Inspecting it later showed that one of the pair of bolts had snapped, and that the other was missing. My guess is that one bolt had worked loose at some point, leaving all the stresses to the other bolt, now compounded by the extra leverage the lack of the second bolt created.

A few things lend credence to my theory. One is that some weeks/months back, during a less-bumpy ride, I had noticed that one of the bolts had worked loose. I was happy to catch it before it got lost, and tightened it up. So, a bolt working loose is not without precedent.

Second is that the video of the descent prior to failure was ridiculously shaky... the extra “give” from the lost bolt showing up in the result.

What still perplexes me, though, is that after noticing the loose screw the first time, I used Loctite 222 to secure them both. I think that there are more different Loctite products than atoms in the universe, but this seemed to be an appropriate one for this situation. Yet, the screw was nowhere to be found. (Had the first screw also broken in half, part of it would have remained in the mount just as part of the second screw remained in the mount.)

K-EDGE mounts are well respected, and the one I had is highly rated at Amazon by what seem to be real reviews. The bolts aside, it seems rock solid, so I sent them a note asking whether they had a unibody version of the mount.

I didn't expect much. A different company (TiGRA), for example, didn't even response when I reached out to them after their mount disintegrated, sending my iPhone 6+ smashing into the pavement.

But K-EDGE responded right away. They noted that they tend to see this kind of separation after a crash. I suppose that in the case of a crash, such a separation is a feature: the mount separates upon impact, lowering the stress on your much-more-pricey bike and accessories (or, more importantly, giving way to your body being flung about instead of impaling a cycling computer in your gut).

In my note to them I didn't ask for anything but information, but in their first response they asked me to fill out a warranty/return form, and asked for more details about the failure. I sent them a bunch of photos and the video that my Fly12 was taking at the time of the failure.

Their second response, which came equally quickly, is a model for excellent customer relations. They had never seen a failure like this, which one supposes would make them skeptical of the story they were hearing, but if they harbored any suspicion, they kept it to themselves. First they addressed the current situation: they said they were expressing me two copies of the mount (at their expense, to my address in Japan, even though I had bought the mount in America), which I could do with what I wanted. They noted that if I didn't trust the mount, I could sell them to fund whatever mount solution I might decide to go with. That last bit about selling them showed me that they weren't just going through the “give him something to shut him up” motions. They truly cared. Seth Godin would be proud. I was impressed.

Then on to why the mount failed in the first place. They said that thought that perhaps “the bolts were over torqued causing them the break under extreme stress”.

This mention of “over torqued” obviously means "we think you must be inhumanly strong... Superman must cower in your presences, and women must swoon at your devastating good looks". It's a plainly-superficial attempt to flatter, and, I must say, remarkably effective. 😀

Seriously, though, I highly doubted that I had over-torqued them, but a couple of messages later they informed me that the torque specification for these screws is 0.88 Newtons. That seems ridiculously low to me... about finger tight? If that's the case, then yes, I certainly did over-tighten them.

There is no mention of this on their web site, the product packaging, or the product itself. That's a big problem. They said they're in the process of updating things to make this information available, but at the moment the only place one can find this information seems to be this blog post. I hope it helps someone.

At this point I don't fully understand why there was a failure, and especially how a bolt could have come loose and gotten lost when I had secured it with Loctite. Maybe the Loctite product I used wasn't appropriate, or maybe I just didn't apply it properly. Or maybe it has a shelf life that I exceeded. (I've had it lying around for ages.)

In any case, I'm willing to give the mount another try so long as I don't mess with the two little screws, leaving them just as they arrived. However, still being a bit leery of the screws, I marked them with nail polish so that I can see at a glance if they make any movement:

For the first few rides I also wrapped them with tape, to physically restrict their ability to just fall out....

Nikon D4 + Venus 60mm Super Macro f/2.8 — 1/30 sec, f/4, ISO 450 — image data

Swaddled Like a Newborn

I rode hundreds of kilometers and there was no apparent movement in the screws, so I got rid of the tape.

The bike-side part is attached to the bike with a screw, and for this screw the unit itself is marked “Max 2Nm”, so I took care to respect that:

Nikon D4 + Venus 60mm Super Macro f/2.8 — 1/30 sec, f/4, ISO 560 — image data

A Bit Shy Of 2 Newton-meters

And of course I'll still certainly use the cord that came with the Fly12 to tether the whole thing to the bike; it saved everything the first time.

So there we have it. K-EDGE seems like a great company with a great product that has not-so-great instructions that most folks won't notice (because most folks, I'd guess, won't fiddle with the screws to begin with). But it seems the tightness really matters, so the information should be out there; that it's not reflects back on the company reducing its “great” rating. Hopefully they can get their site/packaging updated and remove all qualifications for “great”.

I use Loctite in applications with heavy vibrations in my product (industrial power tools) and have found it requires a bit of preparation to work correctly. This preparation is especially important with coated/treated surfaces like that mount has. We have taken to cleaning everything with lacquer thinner, blowing it off with very dry compressed air and applying Loctite’s primer. With those steps you can then go from customers complaining of things falling off to complaining that they can’t take them apart. This proves that engineering is not about fixing problems as much as moving them around.

Just had a similar failure with the same mount, holding an Edge 520 and a fly12. After about 5 months/7500km of riding, noticed movement in the interface on a bumpy ride. Not convenient to stop so held on to it as much as possible but despite this one of the bolts dropped out altogether. Tried to repair with an M3 bolt with the right thread pitch and some blue loctite, but it’s just vibrated loose again on the next ride, so will try and warranty it. I notice that the warranty now says that the mount is not suitable for the fly12 – it didn’t say that before – maybe was updated after your experience and probably that of others. The fly12 is apparently just too heavy for the design to handle, so I would definitely keep using that tether! I’ll probably go back to using separate mounts. Thanks for the useful and interesting post, and also for your exif viewer which I use all the time! Small (virtual) world. Cheers, Tim (from a land down under)

Hi Jeffery. I just had a similar problem. The assembly screws on the bottom of my combo mount dropped out in the middle of my ride. I just emailed K-Edge, but I’m not optimistic. The last time I sent them an email enquiring about a replacement for a lost screw in my GoPro mount I never got an answer.

Do you happen to know what type / size these two little assembly screws are? Apologies if you mentioned it in your post an I missed it.

Thanks,

Steven

I don’t know, sorry. —Jeffrey

Hi Jeffrey,

I cam across your website after seraching about the Kedge mount issue. I have recently bought the garmin combo mount and after using it for about 3 months it felt apart like yours.

I have never touched the screws before and after reading on the Kedge website they do say that we are not suppose to tampered it. It was used with a Knog PWR Road lights on the goprot mount and a Garmin edge 520.

I do see that on their website it does mention that the mount is not designed to support he Cycliq Fly 12.

I am just wondering have you since had any issues with your mount or what happened to yours? Thanks

My Fly12 died (as all Cycliq products seem to do sooner than later), and so I changed the configuration of things such that I no longer use the K-Edge at the moment. —Jeffrey